Reliable solutions for the building materials industry.

Our new milestone is the discerning eye in your running production.

On this page our Masa concrete heads present the latest milestone: The Masa Optical Quality Control System.

At Masa, we think of nothing but concrete

... and how to shape it for the building materials industry. The machines we develop, and manufacture are used for the production of concrete blocks and pavers, sand-lime bricks and aerated concrete blocks. In other words, we are real concrete heads with a passion for reliable machines.

You want to optimize the use of resources but your building material customers only accept minimal tolerances in product quality.

"My milestone ensures consistently high product quality through real-time feedback and automated inspection.”

Marcel Hellen, R&D Department, Masa GreyHUB, Andernach Marcel, one of our clever concrete heads, has developed a tool for paver production lines that provides precise information about the quality of the ongoing production. On the wet side, the system measures products, identifies defects such as cracks, liftings or cement balls and helps you to reduce waste – making your production smarter and more reliable.

Don't miss the next news on this topic! Click to sign up for our milestone newsletter.

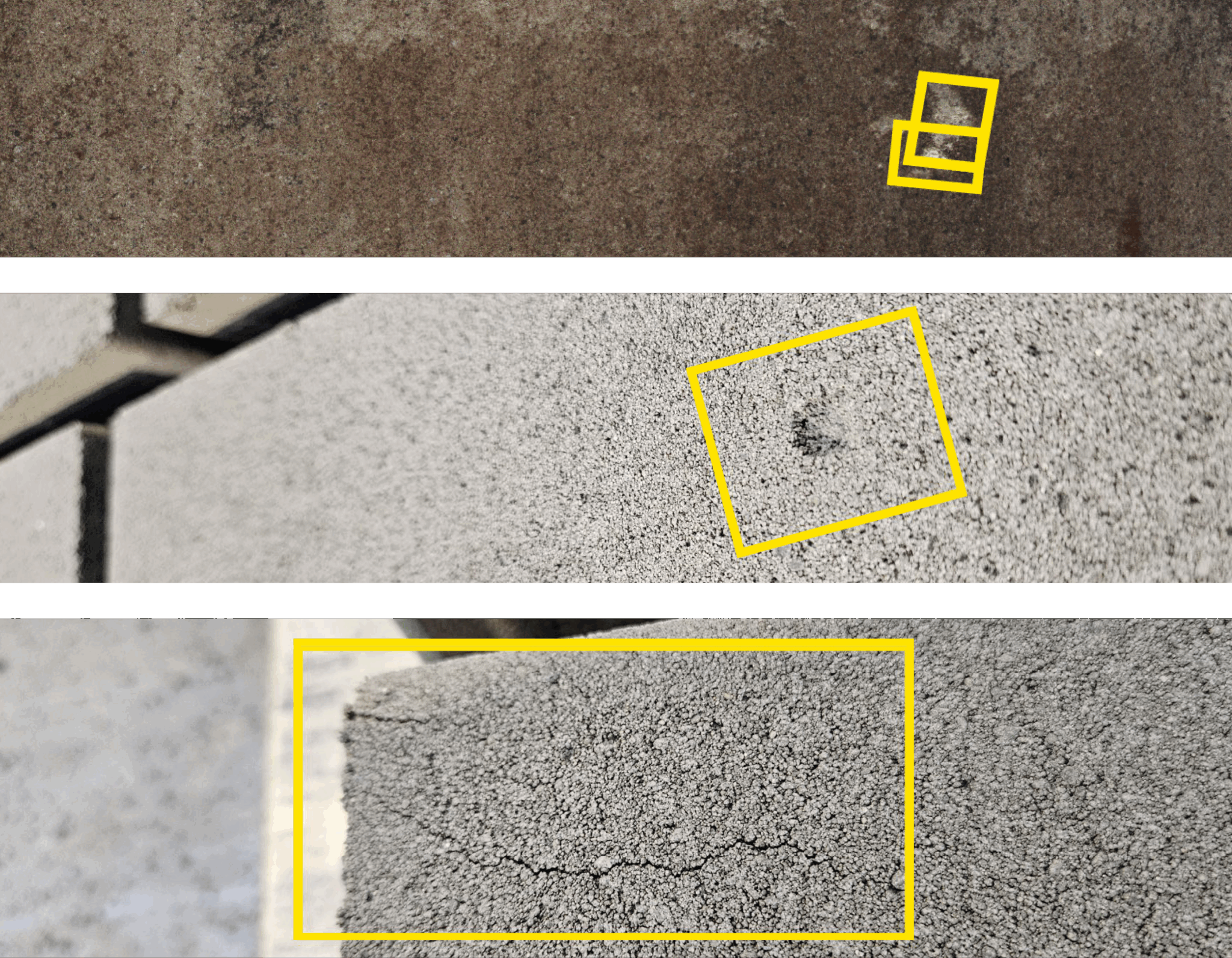

Define quality!

Our Optical Quality Control System gives you full transparency over your production — in real time. Identify defects within seconds and take immediate action to optimize your processes. • Measure product heights • Precise 24/7 inline defect detection with consistent quality. • Immediate analysis for production optimization. • Faster production of sellable blocks. You define the tolerance limits – our system checks your freshly produced concrete products directly behind the machine while production is running: quality control without loss of time!

Don't miss the next news on this topic! Click to sign up for our milestone newsletter.

Precision is the foundation of quality.

“My milestone detects even the smallest deviations, helping you maintain high standards and reduce waste with unmatched accuracy.”

Björn Herborn, R&D Department, Masa GreyHUB, Andernach • Height measurement accuracy +/- 0.5 mm (product height 25 – 500 mm) • Detection of surface defects from a size of approx. 1 mm² • Detection of lifted areas on the surface with a height difference of about 0.5 mm • Detection of fine cracks from a width of approx. 0.5 mm • Differentiation of surface defects and impurities • Detection of cement balls • Classification of defects Thanks to AI-supported analysis, deviations are automatically classified and visualised in real time — fully integrated into the Masa plant control system.

Don't miss the next news on this topic! Click to sign up for our milestone newsletter.

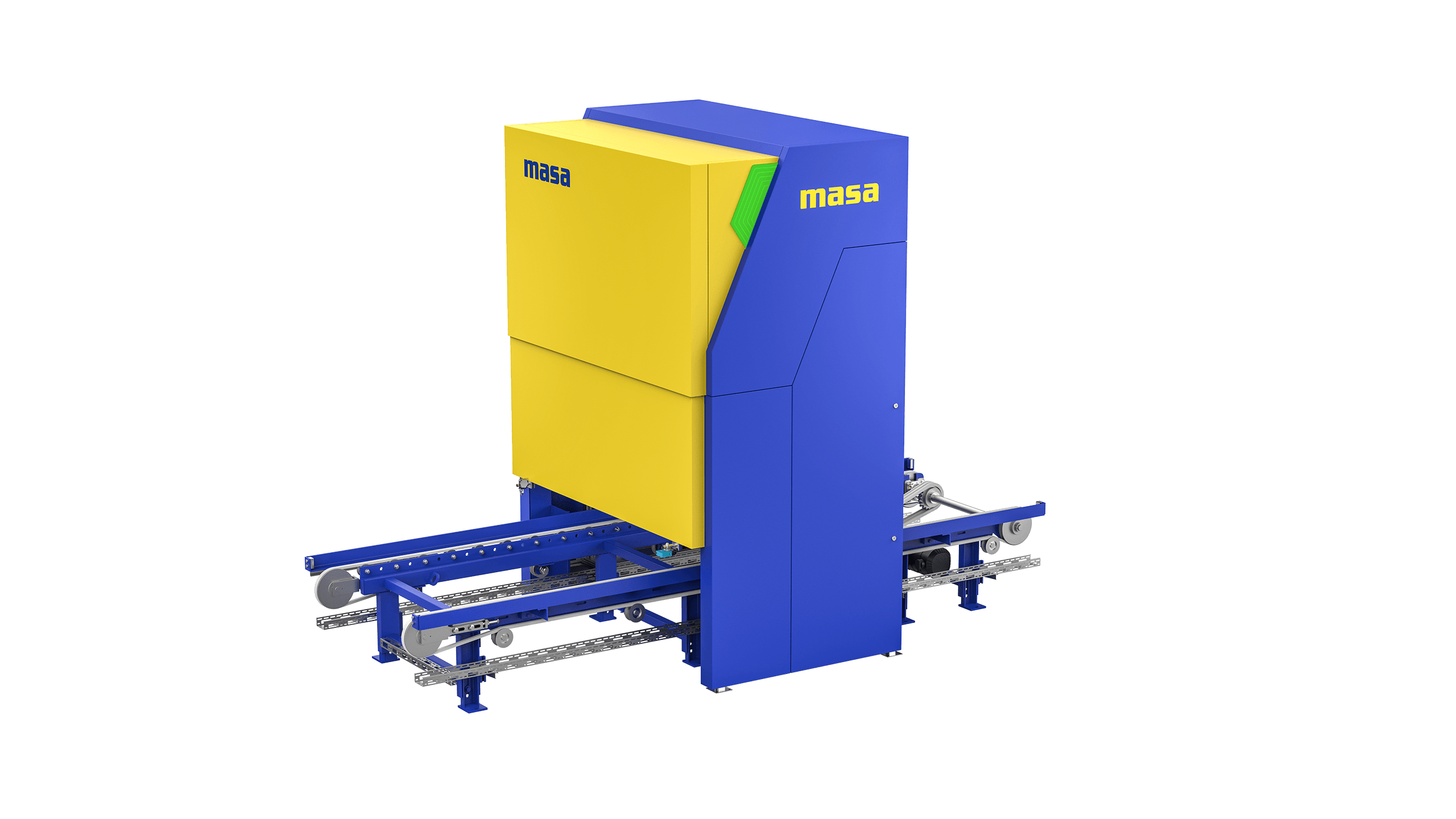

OUR SOLUTION FOR YOUR OPTICAL QUALITY CONTROL

Our Optical Quality Control System combines advanced sensor technology with AI-supported analysis. The result: reliable, contactless inspection directly in your running production.

• Slim design

• 3D surface scanner

• Optical camera system with line lightning

• Distance measuring system wet side conveyor

• Optional scanner for special products

• Integrated into Masa plant control system

Dimensions:

• Width: 86.9 in / 2207 mm

• Height: 117.7 in / 2989 mm

• Depth: 58.1 in / 1476 mm

Subscribe to the newsletter

for news and updates.

Download our bluepaper now!

You can find our different solutions relating to the filling process in our bluepaper “Quality in focus”.